目录

灌溉管道中使用的阀可根据其压力容量分为两类. 一种类型是主要管道中使用的高压阀, 例如铸铁阀, 不锈钢阀, PVC阀, PP阀, 或阀, ETC. 他们的压力容量通常达到 10 到 16 公斤甚至更高.

另一种类型的阀门主要用于旁路管道, 这正是本文将介绍的内容 - 滴灌迷你阀! 他们的压力容量通常约为3-5公斤, 尺寸很小,价格低. 由于旁路管道不需要高水压, 这些迷你阀完全足够. 下一个, 这篇文章将从三个方面引入滴灌迷你阀: 材料, 风格, 和功能.

滴灌迷你阀的材料

图片 1

图片 2

用于滴灌小阀的材料, 目前市场上有两种流行类型: pp (聚丙烯) 和pom (多形甲醛).

由POM制成的滴灌迷你阀 (如图所示 1) 具有非常好的高温阻力和耐磨性, 曾经成为市场上最受欢迎的选择.

然而, 随着市场竞争的加剧, POM的较高材料成本还使滴灌小型阀的成本更高, 因此,迫切需要选择一种新材料来代替POM.

在中国, 一些滴灌迷你阀的制造商在尝试并推出了由PP制成的迷你阀领导 (如图所示 2), 在市场上收到了良好的反馈. 然后越来越多的公司加入了该小组, 最后, PP滴灌迷你阀取代了POM滴灌迷你阀,并成为主流.

PP滴灌迷你阀的成功归因于其成本较高的性能, 他们还可以完全满足滴灌的需求. 第一的, 一般来说, 滴灌产品的使用寿命不是很长, 通常2 - 3年就足够了. 第二, PP材料迷你阀, 经过技术改进, 还可以处理更高的温度并具有很好的衰老抗性. 最后, PP材料的成本远低于POM. 结合这三个优点, PP滴灌迷你阀最终成为市场上新的主流!

滴灌迷你阀的样式

图片 3

图片 4

图片 5

滴灌迷你阀的样式主要由其手柄区别. 在开始, 市场上流行迷你阀的手柄看起来像字母K, 所以他们也被称为AK迷你阀 (如图所示 3).

之后, 然而, 迷你阀的把手更改为更圆的样式 (如图所示 4). 具有这种手柄的迷你阀更强大,在全球市场上取得了很好的销售.

最近几年, 市场上也出现了一些新的小阀的手柄风格 (如图所示 5). 这些阀的手柄具有更好的抓地力,设计更为符合人体工程学.

滴灌迷你阀的功能

滴灌迷你阀可以根据其功能分为两种类型: 直阀和旁路阀.

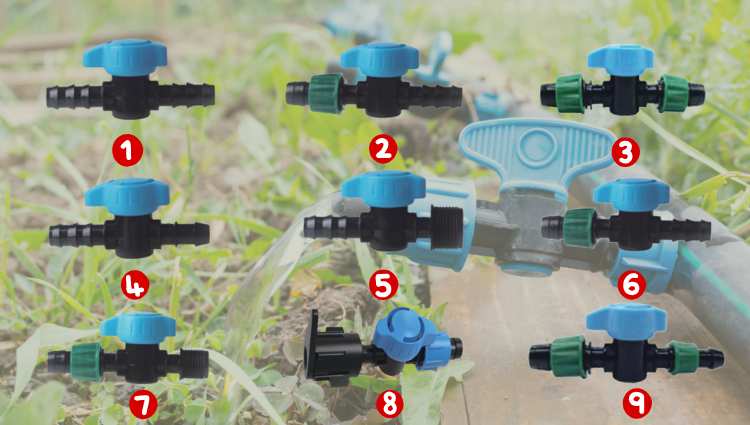

以下是直阀和旁路阀的九种主要连接方法. 在下图中, 显示了与这些九个连接方法相对应的阀门,可以根据数字一一匹配一个.

直阀, 顾名思义, 用于在相同方向上连接直管道, 例如:

1. PE管和PE管之间的连接.

2. 在体育管和滴胶带之间.

3. 在滴胶带和滴胶带之间.

旁路阀, 另一方面, 用于连接主管道和分支管道, 他们可以控制和改变水流的方向. 取决于管道材料的特征, 他们的连接方法也不同。:

4. 硬管之间的连接 (主要管道) 和PE管 (分支管道). 连接时, 小孔需要在硬管中打孔, 然后插入旁路阀的一端. 然而, 确保密封, 连接期间必须使用橡胶戒指.

5. 主管道之间的连接 (螺纹接口) 和PE管 (分支管道).

6. 硬管之间的连接 (主要管道) 和滴胶带 (分支管道). 在连接期间, 还需要在硬管中打孔, 和橡胶戒指应一起使用.

7. 主管道之间的连接 (螺纹接口) 和滴胶带 (分支管道).

8. 躺式软管之间的连接 (主要管道) 和滴胶带 (分支管道).

9. 也有一种旁路阀可以用于连接, 以及分支管道是滴答胶带还是PE滴管. 它提供了更紧密的联系. 然而, 应该注意的是,每当连接到硬管, 必须使用橡胶戒指来防止泄漏.

最后写

作者: 艾伦和迈克尔

编辑: 迈克尔

内容审阅者: 迈克尔